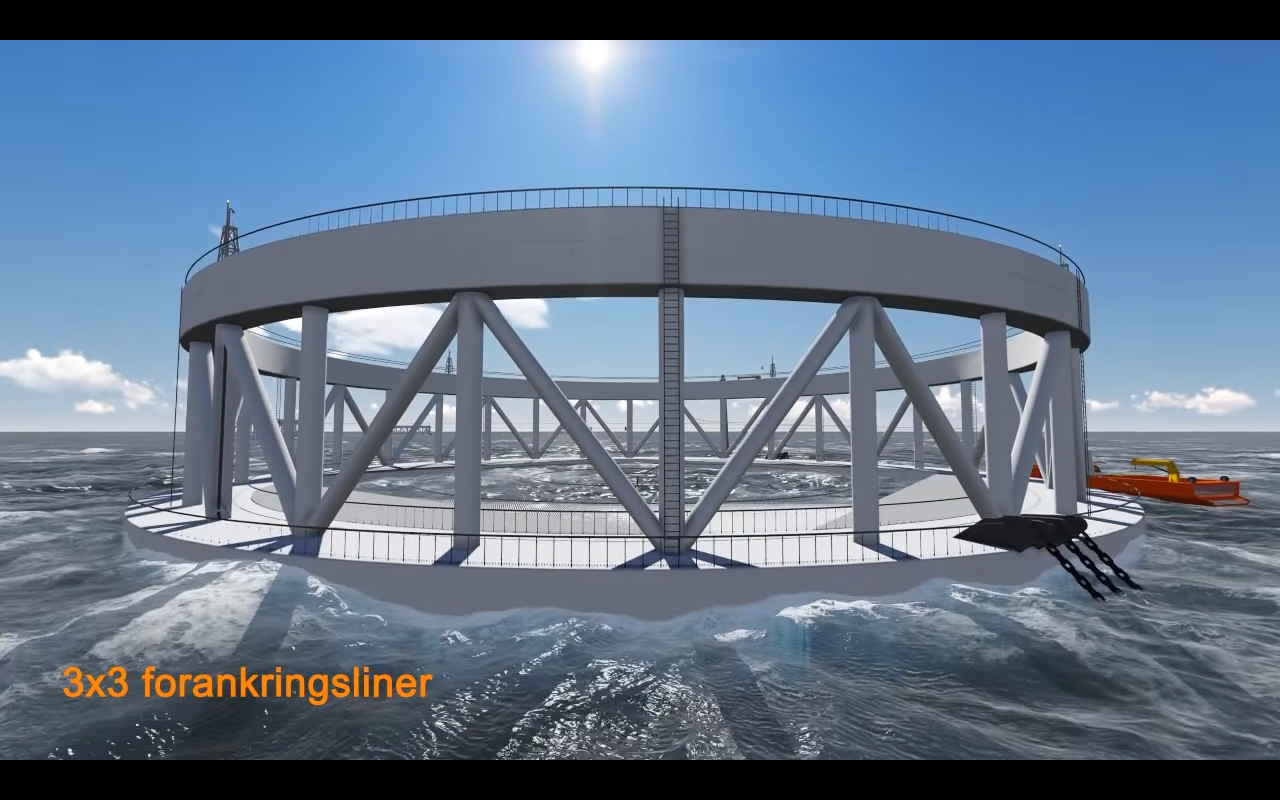

The success of aquaculture can be assured by selecting a site with suitable soil and a high quality water supply, it is essential to understand the pond soil and water characteristics and their optimum requirements to increase the productivity of the ponds.

Optimum soil characteristics

The soils with moderately heavy texture (sandy clay, sandy clay loam and clay loam), electrical conductivity value of 4 dS m-1 or more, pH ranging between 6.5 and 7.5, organic carbon content of 1.5 to 2% and calcium carbonate content of more than 5% are best suited for shrimp aquaculture.

Water quality requirements

Water quality and quantity determines the success or failure of an aquaculture operation. an annual water budget should be calculated for a potential farm site so that the supply is adequate for existing and future needs. Water should be free from pesticides and heavy metals. Maintenance of good water quality is essential for both survival and optimum growth of animals. Water treatment is an important step during pond preparation for the maintenance ofgood water quality at later stage.

Pond preparation

• Pond drying:

Following the harvest after a crop, the deposits of organic debris in the pond bottom should be removed or treated, ploughed, tilled and levelled. all parts of ponds should be thoroughly sun dried for at least three weeks for microbial decomposition of soil organic matter and mineralization of organic nutrients.

Inadequately dried ponds are most likely to develop white spot disease (WSD), running mortality syndrome (RMS) and white gut diseases and premature harvest, whereas, the farms dried from 30 to 45 days would often have successful harvest.

• Lime application can be done based on the pH of the soil and the type of lime available. in soils with chronically low pH it may be beneficial to apply half the total dosage before slight tilling in order to neutralize underlying soil layers.

• After emergency harvest due to white spot disease:

Do not discharge water from white spot disease (WSD) affected ponds. Remove aeration devices and implements and disinfect by evenly distributing calcium hypochlorite to provide a minimum final free chlorine concentration of 10 ppm. allow the system to stand for a minimum of 24–48 hours at this minimal chlorine concentration.

The virus may remain infective as many as 26 days or more in the pond sediment despite sun-drying, in ponds harvested on emergency due to WSD. Drying pond sediment for at least three to four weeks can help in prevention of WSD.

• Source water:

Filter source water first through coarse screens to remove larger aquatic animals and debris and then pump into a supply/settling canal for allowing the suspended particles in the source water to settle before pumping the water into culture ponds. Then, pass the water through a series of progressively finer screens (150–250 μm mesh size) before being introduced into the reservoir.

Chlorinate water in the reservoir with sufficient chlorine (10 ppm) to kill any potential vectors or carriers in the source water collected in the reservoir. For one ha reservoir pond of one meter depth, 150-160 kg of calcium hypochlorite providing 65% active chlorine would give a final concentration of 10 ppm. Vigorously aerate reservoir at least 48 h for de-chlorination to remove residual chlorine.

Soil and water management

• In order to understand the condition of the pond bottom, soil pH, organic matter and redox-potential (Eh) for oxidized/reduced pond bottom condition have to be monitored regularly. The Eh of pond sediment should not exceed -200 mV.

• The water parameters that should be monitored routinely in ponds during culture period are temperature, pH, salinity, dissolved oxygen and transparency.

The pH should be in optimum level of 7.5 to 8.5 and should not vary more than 0.5 in a day.

Variations in salinity not exceeding 5 ppt in a day will help in reducing stress on the shrimp.

The optimum range of transparency is 25-35 cm. Transparency can be measured using secchi disc

The un-ionized form of ammonia nitrogen should be less than 0.1 ppm.

Any detectable concentration of hydrogen sulphide is considered undesirable.

• Periodical water exchange as and when required will help in maintaining the water quality in optimal range. The use of aerators results in mixing of water at surface and bottom and breakdowns the DO and thermal stratification.

• Use of inputs without proven efficiency should be strictly avoided.

• The discharge water from the shrimp ponds has to be allowed into a treatment system pond before letting it into the environment so that the suspended solids may settle at the bottom.

Bình luận bài viết